Hengshui Jrain Frp fiberglass grating

...

2025-08-15 02:38

472

Secondly, the size and power of the jack hammer play a crucial role in determining its cost. A larger, more powerful unit designed for heavy-duty applications will naturally be priced higher than a smaller model intended for lighter tasks. The power source, whether it's powered by compressed air or electricity, also impacts the price. Pneumatic models, which rely on compressed air, tend to be less expensive initially but require a continuous supply of compressed air, adding to the overall operational cost.

...

2025-08-15 02:26

1100

Next comes the application of a primer, which serves as a bonding agent between the old surface and the new layer of fiberglass frp launder. The primer ensures that the repair material will adhere securely, preventing future delamination. Once the primer has dried, layers of fiberglass fabric soaked in resin are applied, building up the thickness and strength of the FRP structure. Each layer must be thoroughly dried and inspected before proceeding to the next one.

frp launder. The primer ensures that the repair material will adhere securely, preventing future delamination. Once the primer has dried, layers of fiberglass fabric soaked in resin are applied, building up the thickness and strength of the FRP structure. Each layer must be thoroughly dried and inspected before proceeding to the next one.

...

2025-08-15 02:26

2053

Despite their benefits, tapered drill rods require careful handling and maintenance to optimize their performance. Regular inspections for wear, damage, or deformation are necessary, as any compromise in the integrity of the taper can affect drilling efficiency and safety.

...

2025-08-15 02:03

167

A hand-held rock drill is a versatile tool that is commonly used in various industries such as mining, construction, and quarrying. This portable drilling machine is designed to bore holes into hard rock surfaces, making it easier for miners and construction workers to extract valuable materials or install equipment.

...

2025-08-15 02:00

1214

The couplings of drilling rods are another area of technological advancement. These connections must withstand tremendous forces, including torsion, compression, and tension. Advanced thread designs and materials science have led to couplings that are more reliable and easier to maintain Advanced thread designs and materials science have led to couplings that are more reliable and easier to maintain Advanced thread designs and materials science have led to couplings that are more reliable and easier to maintain Advanced thread designs and materials science have led to couplings that are more reliable and easier to maintain

Advanced thread designs and materials science have led to couplings that are more reliable and easier to maintain Advanced thread designs and materials science have led to couplings that are more reliable and easier to maintain drilling rod. Breakthroughs in coating technologies have also enhanced their resistance to corrosion, prolonging the lifespan of these valuable assets.

drilling rod. Breakthroughs in coating technologies have also enhanced their resistance to corrosion, prolonging the lifespan of these valuable assets.

...

2025-08-15 01:45

2862

Furthermore, FRP tanks are also environmentally friendly. They require minimal maintenance and have a long service life, reducing the need for frequent replacements and minimizing waste. This not only benefits the environment but also helps businesses save on operational costs in the long run.

...

2025-08-15 01:32

1987

The unique design of these bits also contributes to their superior performance. The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient

The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient The buttons, which are made of tungsten carbide, are strategically placed on the bit body to create a cutting surface that is both aggressive and efficient tungsten carbide button bits. As the bit rotates, the buttons shear through the rock, breaking it into small pieces that can be easily removed.

tungsten carbide button bits. As the bit rotates, the buttons shear through the rock, breaking it into small pieces that can be easily removed.

...

2025-08-15 01:26

1598

Another key benefit of fiberglass field tanks is their versatility. These tanks can be customized to meet specific requirements, including size, shape, and accessories such as fittings and valves

fiberglass field tank. This flexibility makes fiberglass tanks suitable for a wide range of applications, from agricultural irrigation to chemical storage. Additionally, fiberglass tanks can be reinforced with additional layers for increased strength and protection in high-pressure or high-temperature environments.

...

2025-08-15 00:28

2134

...

2025-08-15 00:20

2354

...

2025-08-15 00:20

2354

The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs

The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs

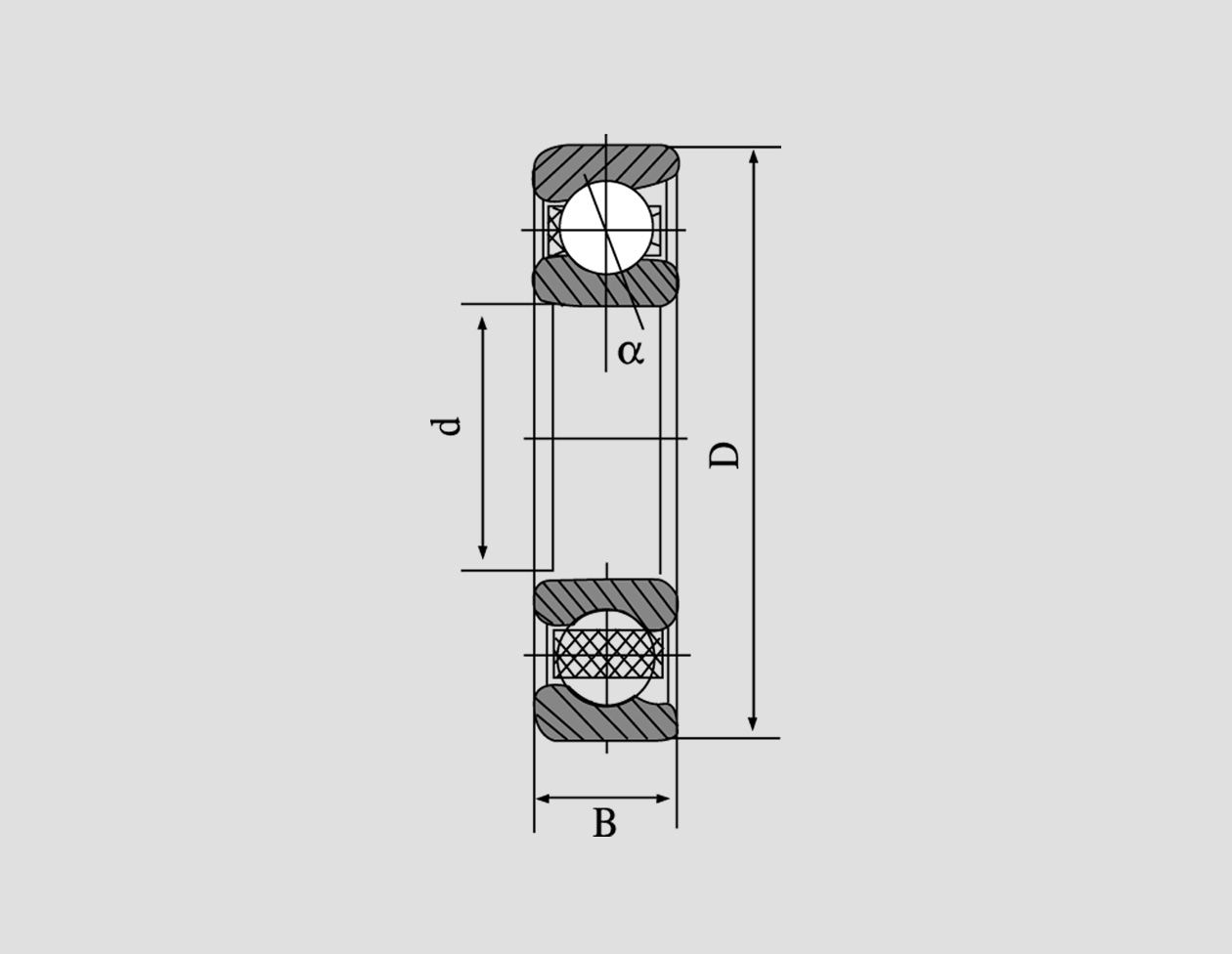

Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments

Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments